Finished product

Next comes steering. With the skilled help of Gilmore & Sons Welding and Fabricating Inc., Dan Gilmore, a friend of my father's, welded the steering arm in place. It looks downright professional! The only problem is attaching it to the frame. I got two control arms with the steering shaft, so what better way to hold it in place? I ground down a tiny bit of the inside of the arm so the shaft could spin relatively freely and drilled a hole in the front pipe to mount it on. I quickly realized the problem... It wouldn't stay in place. Friction alone isn't going to keep it there, so while the steering wheel is mounted, it doesn't quite do a whole lot. However, I did get to clumsily drive around my yard in a circle about once and a half. Then the chain broke. Well, that custom screw I made broke. I have to find a different way to mount that sprocket.

The motors in R/C cars have one side flattened so you tighten the setscrew down there. I'm going to try that with this motor and my trusty Dremel. The chain is fairly loose, so when you let up on the throttle, it goes from the motor pulling the wheel (tension on top) to the wheel pulling the motor (tension on bottom) with this unsettling "chunk" noise. I think the gap between pulling and being pulled is what keeps messing up the sprocket. I need to either really tighten up the chain or fashion some kind of tensioner.

As for brakes, we've decided on a refined version of the stick of wood. We've got these motorcycle chocks that go on a trailer to hold the front wheel of some motorcycles in place. Thus, it is shaped somewhat wheel-like. I figure if I hack off the sides to make it fit around the wheel and mount it to that back bar, i can just use the springiness of the metal itself as a brake. I'd say it's a much more solid plan than the stick of wood, even if it's the same basic principle.

As for brakes, we've decided on a refined version of the stick of wood. We've got these motorcycle chocks that go on a trailer to hold the front wheel of some motorcycles in place. Thus, it is shaped somewhat wheel-like. I figure if I hack off the sides to make it fit around the wheel and mount it to that back bar, i can just use the springiness of the metal itself as a brake. I'd say it's a much more solid plan than the stick of wood, even if it's the same basic principle.If you're having trouble visualizing the brakes, think of a razor scooter.

In the time it took me to post this message, I've gone and gotten that thing welded, by the same guys in fact! So now, it's drivable. It takes some effort to steer, but it works. I added a bar on the back for a passenger to hold on, which tweaks the frame a lot on turns.

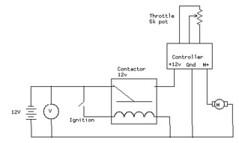

In the time it took me to post this message, I've gone and gotten that thing welded, by the same guys in fact! So now, it's drivable. It takes some effort to steer, but it works. I added a bar on the back for a passenger to hold on, which tweaks the frame a lot on turns. I've also fashioned a new ignition switch that's much more stable than the previous one. Looks better too.

I've also fashioned a new ignition switch that's much more stable than the previous one. Looks better too. My parents threw a graduation party for me and my friends Ryan and Henry where the GoFast was the talk of the town. Many a demonstration was granted and my sister drove it into a tree while I wasn't there (and hadn't given permission). It pulled the wire out of one of the battery clamps, broke the steering column support, mangled my new ignition switch, and popped half the front axle off. Once I had listed all the damage, I fixed it and the steering seems to be working better, which at this point, sounds better than it really is.

My parents threw a graduation party for me and my friends Ryan and Henry where the GoFast was the talk of the town. Many a demonstration was granted and my sister drove it into a tree while I wasn't there (and hadn't given permission). It pulled the wire out of one of the battery clamps, broke the steering column support, mangled my new ignition switch, and popped half the front axle off. Once I had listed all the damage, I fixed it and the steering seems to be working better, which at this point, sounds better than it really is.I aim to provide a video of the GoFast in action soon.